The air brake system, crucial for heavy vehicles, includes compressor, reservoirs, valves, and brake chambers. Ensuring safety and smooth operations on the road.

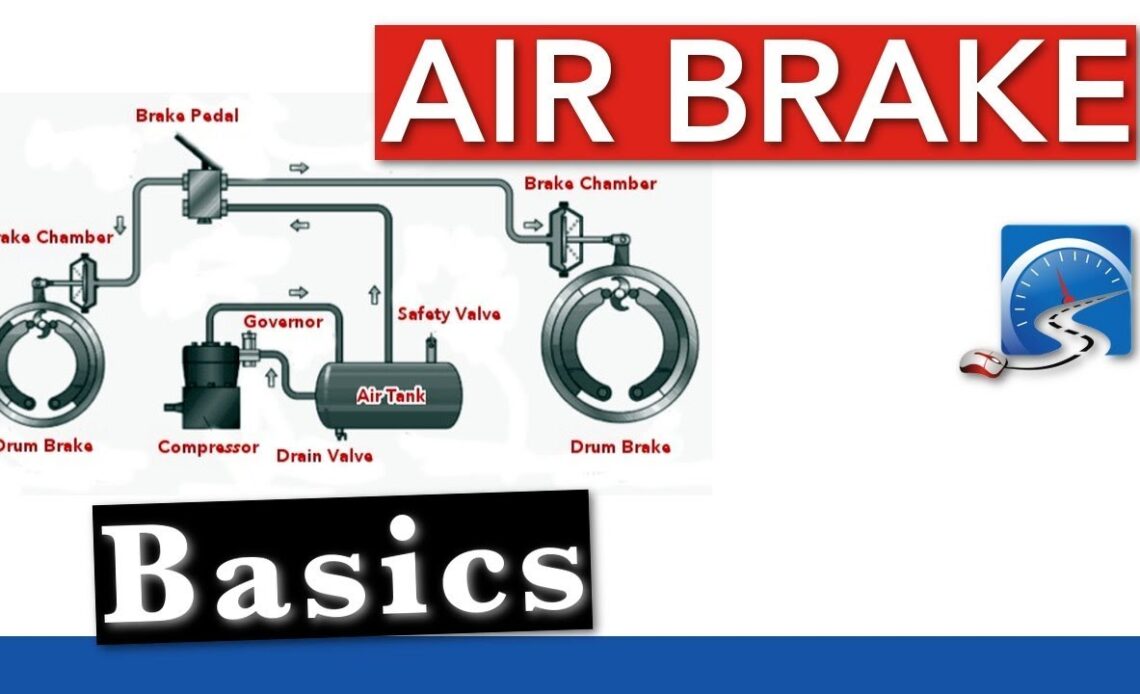

The air brake system is a crucial component of vehicles, especially heavy-duty trucks and buses. It consists of several key components that work together to ensure safe and reliable braking. One of the main components is the air compressor, which pressurizes the system and supplies air to other parts. The air storage tanks store the compressed air, providing a reserve for braking when needed. The brake pedal, valves, and brake chambers control the flow of air and engage the brakes. Additionally, the brake drums and shoes convert the air pressure into mechanical force to stop the vehicle. Understanding these components is essential for maintaining and troubleshooting the air brake system, ensuring optimal performance and safety on the road.

Understanding the Key Components of the Air Brake System

The air brake system is an important safety feature in vehicles, especially in large trucks and buses. It helps in slowing down and stopping these heavy vehicles effectively. To have a better understanding of the air brake system, it is essential to know its key components:

- Air Compressor: This component is responsible for compressing air, which is then stored in the air reservoirs.

- Air Reservoirs: These are storage tanks where the compressed air is stored. They provide an adequate supply of compressed air to various parts of the brake system.

- Foot Valve: The foot valve is operated by the driver’s foot and controls the flow of compressed air to the brake system.

- Brake Chambers: These are pneumatic devices that convert the compressed air into mechanical force to operate the brakes. They are connected to the brake shoes or pads and apply pressure to them to slow down or stop the vehicle.

- Brake Shoes/Pads: These are the parts that come into contact with the brake drums or discs to create friction, which slows down the vehicle.

- Brake Drums/Discs: These are rotating components attached to the wheels that the brake shoes or pads press against to create friction and stop the vehicle.

- Brake Lines and Hoses: These components carry the compressed air from the reservoirs to the brake chambers, ensuring proper operation of the brakes.

- Brake Valves: Various types of brake valves control the flow, distribution, and release of compressed air within the brake system.

- Brake Pedal: The brake pedal is operated by the driver and activates the foot valve, which in turn controls the operation of the brakes.

Understanding these key components of the air brake system is crucial for vehicle operators and technicians to ensure proper maintenance and safe operation of the brakes. Regular inspection, maintenance, and troubleshooting of these components are necessary to prevent brake failure and ensure optimal braking performance.

The air brake system is a vital component in large vehicles such as trucks and buses, as it provides reliable and efficient braking power. Understanding the essential parts of an air brake system is essential for safe operation. Here are the key components:

| Component | Description |

|---|---|

| Air Compressor | Compresses air and stores it in the air reservoirs. |

| Air Reservoirs | Store compressed air and supply it to various parts of the brake system. |

| Foot Valve | Controlled by the driver’s foot, it regulates the flow of compressed air to the brake system. |

| Brake Chambers | Convert compressed air into mechanical force to engage the brakes. |

| Brake Shoes/Pads | Create friction against the brake drums or discs to slow down or stop the vehicle. |

| Brake Drums/Discs | Rotate with the wheels and provide the surface for the brake shoes or pads to press against. |

| Brake Lines and Hoses | Carry the compressed air from the reservoirs to the brake chambers for proper brake operation. |

| Brake Valves | Control the flow, distribution, and release of compressed air within the brake system. |

| Brake Pedal | Activated by the driver, it regulates the operation of the foot valve and engages the brakes. |

These essential parts work together to provide reliable braking performance. Regular maintenance and inspection of the air brake system are crucial to ensure its proper functioning and prevent potential brake failures. By understanding the functions and interactions of these components, vehicle operators and technicians can maintain a safe braking system.

Mastering the Inner Workings of the Air Brake System

The air brake system is a crucial component of any heavy-duty vehicle, ensuring its safe operation on the road. Understanding its inner workings is essential for anyone involved in the maintenance or operation of these vehicles.

To master the inner workings of the air brake system, it is important to understand its key components and how they work together. Here is a breakdown of the main components:

- Air Compressor: The air compressor is responsible for pressurizing the air that powers the brake system. It draws in air and compresses it before sending it to the air storage tanks.

- Air Storage Tanks: These tanks store compressed air, acting as a reservoir for the system. They ensure a constant supply of compressed air is available for braking.

- Brake Pedal: The brake pedal is used by the driver to apply pressure to the braking system. When the pedal is pressed, it sends a signal to release the compressed air and engage the brakes.

- Brake Chambers: Brake chambers are responsible for converting compressed air into mechanical force. When the air is released from the storage tanks, it pushes a piston inside the brake chamber, causing the brake shoes to engage with the brake drums.

- Brake Drums and Shoes: The brake drums are attached to the wheels, while the brake shoes are lined with friction material. When the brake shoes are forced against the brake drums, they create the necessary friction to slow down or stop the vehicle.

- Valves: Various valves control the flow of air throughout the system, ensuring proper operation. These include the relay valve, quick release valve, and check valves.

Understanding the inner workings of each of these components is essential for maintaining and troubleshooting the air brake system. It allows for proper diagnosis and repair of any potential issues that may arise, ensuring the safety and reliability of the vehicle.

Here are the main components that make up the air brake system:

| Component | Description |

|---|---|

| Air Compressor | The air compressor pressurizes the air that powers the brake system. |

| Air Storage Tanks | These tanks store compressed air, providing a reservoir for the system. |

| Brake Pedal | The brake pedal is used by the driver to apply pressure and activate the brakes. |

| Brake Chambers | Brake chambers convert compressed air into mechanical force, engaging the brakes. |

| Brake Drums and Shoes | Brake drums are attached to the wheels, and brake shoes create friction against them to slow down the vehicle. |

| Valves | Various valves control the air flow and pressure within the system. |

: A Comprehensive Guide to the Air Brake System’s Main Elements

The air brake system is a crucial component of any vehicle’s braking system, particularly in larger vehicles such as trucks, buses, and trains. It relies on the force of compressed air to effectively bring a vehicle to a stop. Understanding the main elements of the air brake system is essential for properly maintaining and operating these vehicles.

Here is a comprehensive guide to the main elements of an air brake system:

1. Air Compressor: This component is responsible for compressing air from the vehicle’s engine and storing it in the air reservoirs. It ensures a steady supply of compressed air needed for the proper functioning of the system.

2. Air Reservoirs: These storage tanks hold the compressed air. They play a vital role in providing a reserve of pressurized air to operate various components within the system.

3. Brake Pedal: The brake pedal is the input device that the driver uses to initiate braking. When the driver presses the pedal, it activates the system and controls the amount of air pressure that is applied to the brakes.

4. Brake Chambers: Located at each wheel, brake chambers convert the energy stored in the compressed air into mechanical force. They push the brake shoes or pads against the brake drums or discs, creating friction and stopping the vehicle.

5. Brake Shoes/Pads and Drums/Discs: These components are essential for generating friction and stopping power. Brake shoes or pads are pressed against the brake drums or discs when the air pressure is applied, creating the necessary friction to slow down or stop the vehicle.

6. Control Valves: These valves regulate the flow of compressed air throughout the system. They determine the amount of air pressure applied to brake chambers, allowing for precise control of braking force.

7. Brake Lines and Hoses: These channels carry the compressed air from the air reservoirs to the brake chambers. They need to be in good condition to ensure proper airflow and avoid air leaks.

By understanding these main elements of an air brake system, drivers and maintenance personnel can effectively troubleshoot issues, perform regular inspections, and ensure the system operates at optimal levels.

: The Vital Components You Need to Know in an Air Brake System

In any vehicle equipped with an air brake system, knowing the key components is essential for proper operation and maintenance. These components work together to ensure the vehicle can safely come to a stop using compressed air as the driving force.

Here are the vital components you need to know in an air brake system:

1. Air Compressor: This component pressurizes air from the vehicle’s engine and stores it in the air reservoirs, ensuring a constant supply of compressed air.

2. Air Reservoirs: These reservoirs hold the compressed air and act as a storage tank. They provide an immediate source of pressurized air needed to engage the brakes.

3. Brake Pedal: The driver activates the brakes using the brake pedal, which controls the amount of air pressure applied to the system.

4. Brake Chambers: These chambers are located at each wheel and convert the compressed air’s energy into mechanical force. They engage the brake shoes or pads, creating friction and ultimately stopping the vehicle.

5. Brake Shoes/Pads and Drums/Discs: Brake shoes or pads press against the brake drums or discs, creating friction and stopping power when air pressure is applied.

6. Control Valves: These valves regulate the airflow in the system, determining the amount of air pressure applied to the brake chambers. They allow for precise control of braking force.

7. Brake Lines and Hoses: These are the conduits that transport the compressed air from the reservoirs to the brake chambers. They need to be in good condition to maintain proper airflow and prevent air leaks.

Understanding these vital components of an air brake system is crucial for safe and efficient operation. Regular maintenance and inspection of these components will help ensure the system’s integrity and reliable braking performance.

Unveiling the Secrets Behind the Air Brake System’s Components

The air brake system is a crucial component of vehicles like trucks, buses, and trains, responsible for ensuring safe and efficient braking. To understand its functioning, it’s important to delve into the various components that make up this system.

- Air Compressor: This component plays a vital role in supplying compressed air to the entire system. It compresses atmospheric air and sends it to the air tanks for storage.

- Air Tanks: These tanks store the compressed air from the air compressor. They act as a reservoir and supply the necessary air pressure for the brake system to operate effectively.

- Brake Pedal: The brake pedal is the main control for the driver to initiate the braking action. When pressed, it sends a signal to the air valves to release the compressed air into the brake chambers.

- Air Valves: There are different types of air valves in the air brake system, including relay valves, quick-release valves, and control valves. Each valve has a specific function to regulate air pressure and control the brake operation.

- Brake Chambers: These are air-powered cylinders that convert the compressed air pressure into mechanical force. They push the brake shoes against the brake drums or discs, causing friction and resulting in the vehicle’s braking action.

- Brake Drums/Discs: Brake drums or discs are attached to the vehicle’s wheels and provide the surface for the brake shoes or pads to create friction, ultimately slowing down or bringing the vehicle to a stop.

The proper functioning and maintenance of each of these components are essential for the air brake system to work efficiently and ensure the safety of both the driver and the passengers. Understanding the role of these components allows for better troubleshooting and maintenance practices.

- Air Compressor: This crucial component is responsible for compressing air from the atmosphere and supplying it to the air tanks. It ensures a continuous flow of compressed air throughout the system.

- Air Tanks: These reservoirs store the compressed air provided by the air compressor. They maintain the required air pressure in the system and ensure there is an adequate supply for the brake operation.

- Brake Pedal: The brake pedal serves as the primary control for the driver to initiate the braking process. When pressed, it sends a signal to the air valves to release compressed air into the brake chambers.

- Air Valves: There are various types of air valves, including relay valves, quick-release valves, and control valves. These valves regulate the air pressure and control the distribution of air to different brake chambers.

- Brake Chambers: Brake chambers convert the compressed air pressure into mechanical force. They actuate the brake shoes against the brake drums or discs, generating friction and enabling the vehicle to slow down or stop.

- Brake Drums/Discs: Brake drums or discs are crucial components connected to the wheels of the vehicle. They provide the friction surface for the brake shoes or pads to create resistance, facilitating efficient braking.

The Building Blocks of an Air Brake System and How They Work

In an air brake system, there are several key components that work together to ensure safe and effective braking in vehicles. These building blocks include:

1. Air Compressor: The air compressor is responsible for pressurizing the air in the system. It draws in outside air and compresses it to a higher pressure, typically around 120 to 130 psi (pounds per square inch).

2. Air Reservoirs: Air reservoirs store the compressed air from the compressor. They act as temporary storage tanks for the pressurized air and help maintain a steady supply of air for the brake system.

3. Brake Pedal: The brake pedal is the control mechanism that the driver uses to activate the brakes. When the driver presses down on the brake pedal, it sends a signal to release the compressed air from the reservoirs and apply the brakes.

4. Brake Chambers: Brake chambers are responsible for converting the air pressure into mechanical force. They consist of a diaphragm and a pushrod. When air pressure is applied, the diaphragm pushes the pushrod forward, activating the brakes.

5. Brake Shoes and Drums: Brake shoes are curved metal plates with friction material on the outer surface. They are mounted on the brake drums, which are rotating metal cylinders. When the brakes are engaged, the brake shoes press against the brake drums, creating friction and slowing down the vehicle.

6. Brake Control Valve: The brake control valve is a crucial component that regulates the air pressure in the system. It ensures that the correct amount of pressure is supplied to the brake chambers, allowing for smooth and controlled braking.

7. Air Dryer: The air dryer is responsible for removing moisture from the compressed air. Moisture can corrode and damage the brake components, so the air dryer plays a crucial role in maintaining the integrity of the system.

In summary, the air brake system relies on the interaction of these key components to convert compressed air into mechanical force and effectively apply the brakes. Each component has a specific function and contributes to the overall performance and safety of the system.

Digging Deeper into the Mechanics of the Air Brake System’s Components

To gain a deeper understanding of how the air brake system works, let’s delve into the mechanics of its various components:

1. Air Compressor: The air compressor uses a piston mechanism to draw in outside air and compress it. It typically operates using a belt-driven or direct-drive system. As the piston moves, it compresses the air, increasing its pressure and forcing it into the air reservoirs.

2. Air Reservoirs: The air reservoirs serve as temporary storage tanks for the pressurized air from the compressor. They are designed to hold a specific volume of air and ensure a steady supply to the brake system. The reservoirs have safety valves to prevent over-pressurization.

3. Brake Pedal: When the driver presses the brake pedal, it activates a valve that allows the compressed air to flow into the brake chambers. The valve releases the air pressure, causing the diaphragm in the brake chamber to move and apply force to the pushrod.

4. Brake Chambers: The brake chambers play a crucial role in converting the air pressure into mechanical force. They consist of a diaphragm and a pushrod. When the air pressure is released into the chamber, it pushes the diaphragm forward, which in turn pushes the pushrod. This mechanical force is transmitted to the brake shoes.

5. Brake Shoes and Drums: The brake shoes are mounted on the brake drums, which are attached to the wheels. When the pushrod is activated, it forces the brake shoes against the brake drums. The resulting friction between the brake shoes and drums slows down the rotation of the wheels, leading to braking action.

7. Air Dryer: The air dryer is essential for maintaining the integrity of the air brake system by removing moisture from the compressed air. It typically uses a desiccant material or a cooling process to remove water vapor and prevent corrosion or damage to the brake components.

By understanding the mechanical workings of each component in the air brake system, we can appreciate the intricate design and functionality that enables safe and reliable braking in vehicles.

For detailed information, you can contact us: Torque