Mastering Air Suspension Kit Systems: A Comprehensive Guide

Introduction to Air Suspension Kit Systems

Air suspension kit systems have revolutionized the automotive industry, offering a level of comfort, performance, and versatility unparalleled by traditional suspension setups. Understanding the fundamentals of air suspension is crucial for enthusiasts and everyday drivers alike. In this chapter, we’ll embark on a journey to uncover the essence of air suspension, exploring its mechanisms, benefits, and applications.

Air suspension operates on a simple yet ingenious principle: instead of relying on metal coils or leaf springs, it utilizes air-filled bags or “air springs” to support the vehicle’s weight. These air springs are connected to a compressor and a series of valves, allowing for precise control over ride height and stiffness. Whether it’s lowering the car for improved aerodynamics on the highway or raising it to clear obstacles off-road, air suspension offers unparalleled adaptability.

The advantages of air suspension extend far beyond mere adjustability. By distributing weight more evenly across all four corners of the vehicle, air suspension reduces body roll and improves handling, especially during cornering and heavy braking. Moreover, the ability to fine-tune ride height enhances comfort and stability, regardless of load or driving conditions.

From luxury sedans to rugged off-road trucks, air suspension has found its way into a wide array of vehicles, catering to diverse needs and preferences. Whether you’re seeking a smoother commute or enhanced off-road capability, air suspension holds the key to unlocking a new realm of driving experience.

In the subsequent chapters, we’ll delve deeper into the intricacies of air suspension, exploring its components, installation process, maintenance requirements, and more. So buckle up as we embark on this enlightening journey through the world of air suspension kit systems.

Components of an Air Suspension Kit

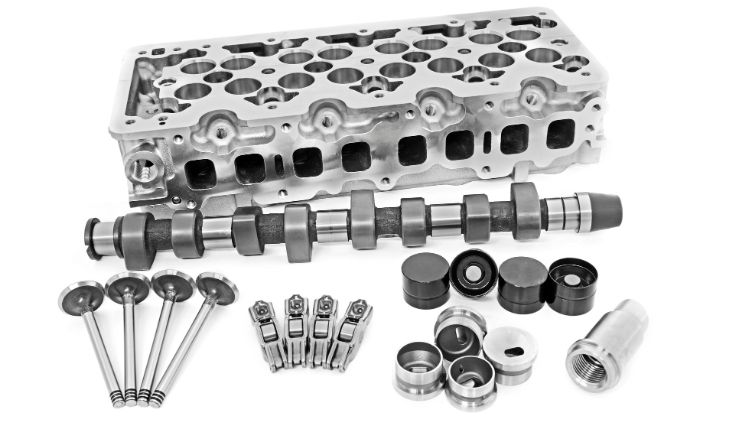

Understanding the components of an air suspension kit is essential for grasping how this innovative system operates. Each part plays a crucial role in ensuring optimal performance and ride quality. In this chapter, we’ll dissect the key components that make up an air suspension kit and delve into their functions.

-

Air Springs

: Also known as airbags, air springs are the heart of the air suspension system. These flexible rubber or polyurethane bags are filled with compressed air and act as the primary means of supporting the vehicle’s weight. They replace traditional coil springs or leaf springs and provide a smoother ride by absorbing road imperfections.

- Air Compressor: The air compressor is responsible for generating and supplying compressed air to the air springs. It pressurizes the air, allowing for adjustments to the ride height and stiffness of the suspension. The compressor typically features a built-in dryer to remove moisture from the air, preventing corrosion within the system.

- Valves and Lines: Valves regulate the flow of air between the compressor, air springs, and reservoir. They control the suspension’s behavior, allowing for adjustments based on driving conditions and driver preferences. High-quality pneumatic lines connect the components, ensuring airtight seals and efficient air delivery.

- Control System: The control system serves as the brain of the air suspension kit, monitoring vehicle sensors and driver inputs to adjust ride height and stiffness automatically. Advanced systems may feature electronic controllers with programmable settings, enabling precise customization of suspension parameters.

By understanding how these components work together, enthusiasts can gain insight into the inner workings of their air suspension kit. In the following chapters, we’ll explore the installation process, types of air suspension kits, and maintenance tips to ensure optimal performance and longevity.

Types of Air Suspension Kits

Air suspension kits come in various configurations, each tailored to meet specific performance goals and vehicle requirements. Understanding the different types of air suspension kits is crucial for selecting the right setup for your needs. In this chapter, we’ll explore the various types of air suspension kits available in the market and discuss their advantages and applications.

-

Full Air Suspension Kits

: Full air suspension kits replace the entire factory suspension setup with air springs and associated components. These kits offer the highest level of adjustability, allowing drivers to control ride height, stiffness, and damping characteristics electronically or manually. Full air suspension kits are popular among enthusiasts seeking maximum customization and performance.

- Coilover Conversion Kits: Coilover conversion kits combine the benefits of traditional coilover suspension with the versatility of air springs. These kits feature adjustable coilover shocks or struts paired with air springs, providing the ability to fine-tune ride height and damping settings. Coilover conversion kits are favored by performance-oriented drivers who demand precise handling and adjustability.

- Airbag Helper Spring Kits: Airbag helper spring kits are designed to augment existing coil or leaf spring suspensions with supplemental air springs. These kits are ideal for vehicles that require additional load support, such as trucks towing heavy trailers or carrying heavy payloads. Airbag helper spring kits improve ride quality and stability without the need for a complete suspension overhaul.

Choosing the right type of air suspension kit depends on factors such as vehicle application, desired performance characteristics, and budget. Whether you’re aiming for track-ready handling, enhanced towing capability, or a smoother ride for daily commuting, there’s an air suspension kit suited to your needs. In the following chapters, we’ll delve deeper into the installation process, maintenance requirements, and customization options for air suspension systems.

Installation Process

Installing an air suspension kit requires careful planning, precision, and attention to detail to ensure optimal performance and safety. In this chapter, we’ll provide a step-by-step guide to the installation process, covering everything from preparation to system calibration.

-

Preparation

: Before beginning the installation, gather all necessary tools and equipment as specified in the kit’s instructions. Ensure the vehicle is parked on a level surface and safely supported with jack stands. Disconnect the battery to prevent electrical mishaps during the installation process.

- Component Installation: Start by installing the air springs at each corner of the vehicle according to the manufacturer’s guidelines. Mount the air compressor and reservoir in a secure location, preferably away from excessive heat and moisture. Route the pneumatic lines carefully, avoiding sharp edges or moving parts that could cause damage.

- Wiring and Control Setup: Connect the wiring harnesses included with the kit, following the provided wiring diagrams. This typically involves connecting the compressor, valves, and control module to the vehicle’s electrical system. Ensure all connections are secure and insulated to prevent shorts or electrical malfunctions.

- System Calibration: Once all components are installed and connected, it’s time to calibrate the air suspension system. Turn on the vehicle’s ignition and activate the control module to initialize the system. Follow the calibration procedure outlined in the user manual, which may involve adjusting ride height settings and testing the system’s responsiveness.

- Final Checks: After calibration, perform a thorough inspection of the entire installation to ensure everything is secure and functioning correctly. Check for leaks in the pneumatic lines or fittings using soapy water or a leak detection solution. Test the suspension by cycling through various ride height settings and driving the vehicle to verify proper operation.

By following these steps meticulously and adhering to the manufacturer’s instructions, you can successfully install an air suspension kit on your vehicle. In the subsequent chapters, we’ll explore maintenance tips, troubleshooting techniques, and advanced customization options for air suspension systems.

Maintenance and Care

Maintaining an air suspension system is essential for ensuring longevity, optimal performance, and safety. In this chapter, we’ll discuss the importance of regular maintenance and provide practical tips for caring for your air suspension kit.

-

Inspect for Leaks

: Periodically check all pneumatic lines, fittings, and air springs for signs of leaks. Use a soapy water solution to identify any bubbles that indicate air escaping. Address any leaks promptly to prevent loss of pressure and potential system failure.

- Monitor Air Pressure: Keep an eye on the air pressure within the air springs using a quality air pressure gauge. Ensure that the pressure remains within the recommended range specified by the manufacturer. Adjust as necessary to maintain proper ride height and suspension performance.

- Service the Compressor: The air compressor is the heart of the air suspension system. Regularly inspect the compressor for signs of wear or damage, such as worn-out belts or leaking seals. Follow the manufacturer’s recommendations for servicing intervals and lubrication to prolong its lifespan.

- Check for Wear and Tear: Routinely inspect all components of the air suspension system for wear and tear, including air springs, shocks or struts, and mounting hardware. Replace any worn or damaged parts promptly to prevent further deterioration and ensure safe operation.

- Calibration and Adjustment: Periodically recalibrate the air suspension system to maintain optimal ride height and performance. Check and adjust the settings on the control module as needed, especially after significant changes in vehicle load or driving conditions.

- Protect from Environmental Factors: Shield the air suspension components from exposure to harsh environmental elements, such as extreme heat, cold, or moisture. Consider installing protective covers or shields to minimize corrosion and prolong the lifespan of the system.

By incorporating these maintenance practices into your routine, you can prolong the lifespan of your air suspension kit and enjoy reliable performance for years to come. In the following chapters, we’ll explore common issues and troubleshooting techniques to address any problems that may arise with your air suspension system.

Common Issues and Troubleshooting

While air suspension systems offer numerous benefits, they may encounter occasional issues that require troubleshooting and resolution. In this chapter, we’ll explore some common problems that air suspension users may encounter and provide effective troubleshooting techniques.

-

Air Leaks

: One of the most prevalent issues with air suspension systems is air leaks. These leaks can occur in pneumatic lines, fittings, or air springs, leading to loss of pressure and compromised performance. Use a soapy water solution to identify and locate any leaks, then repair or replace the affected components as necessary.

- Compressor Failure: A failing or malfunctioning air compressor can result in inadequate air supply to the air springs, causing uneven ride height or suspension instability. Check the compressor for signs of wear, such as unusual noises or excessive vibration, and replace it if necessary.

- Uneven Ride Height: If one corner or side of the vehicle sits lower than the others, it may indicate a problem with the air spring or suspension linkage. Inspect the affected components for damage or wear, and ensure that the air springs are inflated to the correct pressure. Adjust as needed to restore uniform ride height.

- Harsh Ride Quality: Excessive stiffness or harsh ride quality can be attributed to improper adjustment of damping settings or overinflated air springs. Review the settings on the control module and adjust the damping and pressure settings to achieve the desired ride comfort.

- Electrical Issues: Electrical problems, such as faulty wiring or sensor malfunctions, can disrupt the operation of the air suspension system. Check all electrical connections for proper seating and continuity, and use a multimeter to diagnose any wiring or sensor issues.

- System Calibration: If the air suspension system fails to respond to adjustments or exhibits erratic behavior, it may require recalibration. Follow the manufacturer’s instructions for recalibrating the system, ensuring proper initialization and adjustment of ride height settings.

By addressing these common issues promptly and effectively, you can maintain the performance and reliability of your air suspension system. In the next chapter, we’ll explore upgrades and accessories that can enhance the functionality and convenience of your air suspension kit.

Upgrades and Accessories

Enhancing your air suspension system with upgrades and accessories can unlock new levels of performance, comfort, and convenience. In this chapter, we’ll explore a variety of aftermarket upgrades and accessories available for air suspension kits.

-

Adjustable Dampers

: Upgrading to adjustable dampers allows for fine-tuning of suspension stiffness and damping characteristics. These dampers offer increased control over ride quality and handling, allowing drivers to tailor their suspension setup to suit their preferences and driving conditions.

- Electronic Height Control Systems: Electronic height control systems provide advanced functionality for adjusting ride height and stiffness on the fly. These systems typically feature electronic controllers with preset modes for various driving scenarios, such as comfort, sport, or off-road. Electronic height control systems offer convenience and versatility, allowing drivers to switch between different ride heights with the push of a button.

- Onboard Air Management Systems: Onboard air management systems provide a centralized solution for controlling air suspension components, such as compressors, valves, and air tanks. These systems offer convenient access to air pressure adjustments and allow for rapid inflation or deflation of the air springs. Onboard air management systems are popular among off-road enthusiasts and show car builders seeking maximum flexibility and performance.

- Remote Control Systems: Remote control systems enable wireless operation of air suspension components, allowing drivers to adjust ride height and stiffness from outside the vehicle. These systems often feature compact remote controls with intuitive interfaces, making it easy to make on-the-fly adjustments without having to access the interior of the vehicle.

- Performance Upgrades: Performance-oriented upgrades, such as upgraded air springs, high-performance dampers, and reinforced suspension components, can further enhance the handling and stability of your air suspension system. These upgrades are designed to withstand the rigors of spirited driving and provide improved performance on the track or street.

By incorporating these upgrades and accessories into your air suspension system, you can customize your vehicle to meet your specific performance and comfort requirements. In the final chapter, we’ll summarize key points covered in this guide and offer recommendations for maximizing the benefits of your air suspension kit.

Conclusion and Recommendations

As we conclude our exploration of air suspension kit systems, it’s evident that these innovative setups offer a multitude of benefits, from enhanced ride quality to improved performance and versatility. Throughout this guide, we’ve delved into the intricacies of air suspension, covering everything from its fundamental components to installation, maintenance, and upgrades.

By understanding the principles of air suspension and following best practices for installation and maintenance, enthusiasts can unlock the full potential of their vehicles, enjoying a smoother, more controlled ride with the ability to tailor suspension settings to their preferences.

As a final recap, here are some key takeaways and recommendations for those considering or already utilizing air suspension kits:

-

Research and Planning

: Before investing in an air suspension kit, thoroughly research the available options and consider your vehicle’s specific requirements and intended use. Proper planning and preparation are crucial for a successful installation and long-term satisfaction.

- Quality Components: Opt for high-quality air suspension components from reputable manufacturers to ensure reliability, performance, and safety. Investing in quality upfront can save you time and money on repairs and replacements down the line.

- Regular Maintenance: Keep your air suspension system in top condition by performing regular maintenance tasks, such as inspecting for leaks, monitoring air pressure, and servicing components as needed. Preventative maintenance can help avoid costly repairs and downtime.

- Upgrade Wisely: Consider aftermarket upgrades and accessories to enhance the functionality and convenience of your air suspension system. Whether it’s adjustable dampers, electronic height control systems, or performance upgrades, choose upgrades that align with your driving preferences and goals.

- Professional Installation: If you’re not confident in your ability to install an air suspension kit yourself, consider hiring a professional installer with experience in air suspension systems. A properly installed system ensures optimal performance and safety.

By following these recommendations and taking a proactive approach to maintenance and upgrades, you can maximize the benefits of your air suspension kit and enjoy a superior driving experience for years to come. Thank you for joining us on this journey through the world of air suspension kit systems.

For detailed information, you can contact us at torqueusa.com.